Dans l'industrie de l'impression moderne, un équipement d'impression efficace et précis est la clé pour assurer la qualité et l'efficacité de la production.

Nom du produit :

Printing machineNuméro d'article :

GC-850-6SCommande (MOQ) :

1Paiement :

30% advance payment, 70% balance before shipment or negotiableOrigine du produit :

xiamen,chinaPort d'expédition :

XIAMEN or Or according to your needsDélai de mise en œuvre :

3 monthsImprimerie

Dans l'industrie de l'imprimerie moderne, la machine de processus d'impression flexible efficace et précise est la clé pour assurer la qualité et l'efficacité de la production. Avec ses excellentes performances et ses technologies avancées, la presse à imprimer flexographique GC 4 + 4 - 850 est un choix idéal pour imprimer des matériaux larges et minces. Qu'il s'agisse d'un rouleau de tissus tissés PP ou d'autres matériaux avec des exigences à haute tension, cette presse à imprimer peut facilement le gérer, garantissant que chaque impression atteint les normes les plus élevées.

Points forts de l'équipement

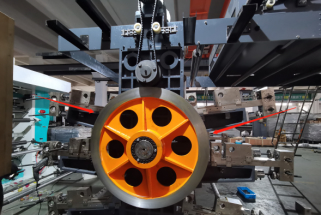

1. Technologie d'impression flexographique par satellite, précision élevée de surimpression

Le GC 4 + 4 - 850 Flexographic Printing Press adopte la technologie d'impression flexographique par satellite. Le matériau imprimé est proche du cylindre d'impression commun, avec de petites modifications de tension et une déformation des petits matériaux pendant le séchage. La machine a une structure compacte et une courte ligne d'alimentation en papier. Il convient particulièrement à l'impression de matériaux larges et minces avec un contrôle difficile de la tension. La précision de surimpression est extrêmement élevée, garantissant que chaque couleur est alignée avec précision.

2. Impression efficace, à la fois la vitesse et la qualité

La vitesse maximale de cette presse à imprimer peut atteindre 200 m / min, et la vitesse d'impression est de 50 à 150 m / min, ce qui convient à une variété de besoins d'impression. Qu'il s'agisse d'impression à 4 couleurs sur l'avant ou d'impression en 4 couleurs à l'arrière, GC 4 + 4 - 850 peut facilement y faire face, assurant une production efficace tout en maintenant une excellente qualité d'impression.

3. Contrôle automatique, opération facile

La machine d'impression flexo de 6 couleurs en Chine est équipée d'un système de contrôle automatique avancé, y compris un réglage automatique de la tension, une correction de déviation automatique, un lecteur de servomoteur, etc., pour garantir que chaque lien du processus d'impression est précis et correct. Le système de correction de déviation EPC automatique et la fonction d'enregistrement électronique en ligne facilitent l'opération, réduisent l'intervention manuelle et améliorent l'efficacité de la production.

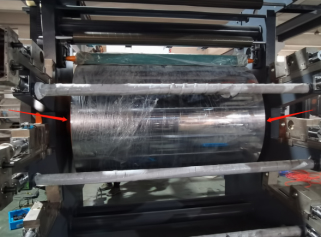

4. Configuration multifonctionnelle, forte adaptabilité

GC 4 + 4 - 850 La machine à imprimer flexographique est équipée d'un système de détente et de rembobinage à double station, soutenant un diamètre de bobine maximal de 1500 mm et s'adaptant à une variété de largeurs de matériau (550-850 mm). L'équipement est également équipé d'un système de séchage, d'un système de refroidissement, d'un dispositif de traitement de la couronne, etc. pour s'assurer que le matériau imprimé est rapidement séché et maintient un bon effet de traitement de surface.

Détails techniques

Matériel d'impression: Roll PP tissu tissé

Largeur du matériau: 550-850 mm

Largeur d'impression maximale: 700 mm

Plage de répétition d'impression: 400-1200 mm

Précision d'enregistrement: horizontal ± 0,15 mm, vertical ± 0,15 mm

Consommation d'énergie totale: 125KW

Poids de la machine: environ 20 tonnes

Taille de la machine: 16,8 m (longueur) x 3 m (largeur) x 4,3 m (hauteur)

Configuration de base

| Traction du servomoteur: | 1 set |

| Machine d'impression satellite: | 2 ensembles |

| Système de séchage d'unité d'impression: | 2 ensembles |

| Système de séchage: | |

| Dispositif de traitement Corona: | 1 set |

| Système de détection vidéo: | 2 ensembles |

| Système de température constante de rouleau central: | 2 ensembles |

| Grattoir fermé: | 8 ensembles (technologie danoise importée) |

| Rouleau d'impression: | 8 pièces (taille personnalisée selon les exigences du client) |

Liste de pièces

GC 4 + 4 - 850 Flexographic Printing Press utilise de nombreuses pièces de marque de renommée internationale pour assurer la stabilité et la durabilité de l'équipement. Les principaux composants comprennent:

Interface humaine-machine: Huichuan

Contrôle de programmation PLC: Huichuan

Servomoteur: Shanghai Danma

Système de correction: Allemagne Meilleur

Rouleau en céramique Anilox: Shanghai Murata (technologie japonaise)

Roulements principaux: Allemagne Fag / Japon NSK

Composants pneumatiques: Taiwan Airtac

Valve proportionnelle électrique: Japon Fujikura

Champs applicables

GC 4 + 4 - 850 La presse à imprime flexographique est largement utilisée dans l'impression dans les champs d'emballage, d'étiquettes, de films, de sacs tissés, etc., particulièrement adaptés à l'impression de matériaux larges et minces avec des exigences élevées pour une précision de sursis. Qu'il s'agisse de production de masse ou d'impression de haute précision, cette machine d'impression Flexo Stack peut répondre à vos besoins