GCPL-G130X33-1800 La machine à dessin de fils d'extrusion en plastique est une ligne de production automatisée haute performance conçue pour les matières premières en polypropylène (PP).

Nom du produit :

Plastic tape extrusion stretching lineNuméro d'article :

GCPL-G130X33-1800Commande (MOQ) :

1Paiement :

30% advance payment, 70% balance before shipment or negotiableOrigine du produit :

xiamen,chinaPort d'expédition :

XIAMEN or Or according to your needsDélai de mise en œuvre :

3 monthsLigne d'étirement d'extrusion de bande en plastique

GCPL-G130X33-1800 La machine à dessin de fils d'extrusion en plastique est une ligne de production automatisée haute performance conçue pour les matières premières en polypropylène (PP). Il intègre un contrôle intelligent, une extrusion efficace et un moulage de précision. Il convient à la production de fils plats en plastique de haute précision, de ceintures tressées et d'autres produits. L'équipement adopte la technologie de pointe internationale et est équipé de composants de base de plusieurs marques pour assurer la stabilité de la production et la qualité des produits. C'est un choix idéal pour l'industrie du dessin en fil plastique.

Avantages de base

Contrôle d'automatisation intelligent

Système de contrôle principal: contrôleur programmable de Taiwan Delta PLC, prend en charge la régulation de vitesse synchrone de la ligne entière, le démarrage et l'arrêt d'un bouton, et l'interface de fonctionnement est équipée de l'écran tactile Kunlun Tongtai (KLTT), qui est intuitif et facile à utiliser.

Contrôle de la température précis: Japon Fuji PID Digital Afficher le compteur de contrôle de température, ± 1 ℃ Précision, contrôle de chauffage à 7 zones, pour assurer une fusion uniforme des matériaux.

Protection de la sécurité multiple: protection contre la surcharge de l'hôte, arrêt d'alarme de surpression dans la zone à langer d'écran, protection de mise à la terre en trois phases, pour assurer pleinement la sécurité de la production.

Performance de production efficace

Conception de vis: φ130 mm à haute résistance à la vis 38Crmoala, rapport d'aspect 33: 1, capacité d'extrusion maximale de 500 kg / h, vitesse réglable 20-100rpm, adaptée à de nouveaux matériaux et à la production mélangée MasterBatch.

Changeur d'écran automatique: Changeur d'écran automatique de la courroie à double mailles (100 + 200 maille), prend en charge la production continue et réduit les temps d'arrêt.

Précision Die Head: 1800 mm Hentier de chauffage interne Tête de piste de spirale, Film Lip Gap 0.3-0,6 mm Réglable, largeur de film 1680 mm, s'adapter aux besoins diversifiés du produit.

Conception de structure modulaire

Système de refroidissement: tous les réservoirs d'eau de refroidissement à débit stable en acier inoxydable, capacité de 1,2 m³, température de l'eau 30-60 ℃ Contrôlable, forme rapide.

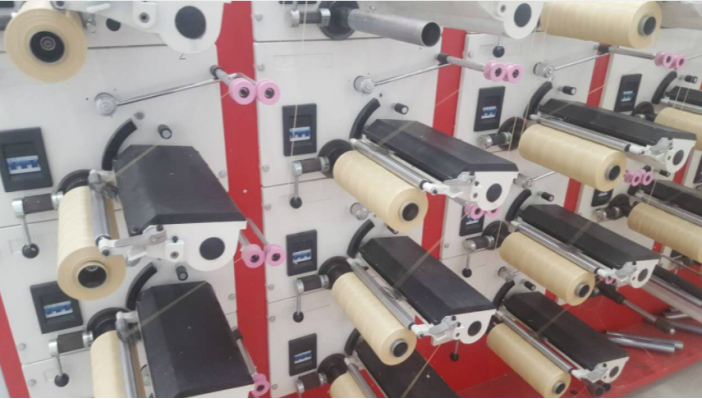

Étirement et mise en forme: la machine d'étirement à 4 rouleaux et la machine de mise en forme sont équipées d'un réducteur Nord allemand, d'une vitesse de ligne 80-400m / min, de la surface du rouleau dur chromé, à l'usure et facile à nettoyer.

Efficacité élevée de l'enroulement: machine d'enroulement à fréquence variable à 30 broches, vitesse d'enroulement maximale 450 m / min, prend en charge φ160 mm en bobine, changement automatique des bobines.

Protection de l'environnement et économie d'énergie

Système de brassage et de recyclage du fil des déchets: capacité de traitement de 20 kg / h, équipé d'un ventilateur de haute puissance de 15 kW, pour obtenir un recyclage du fil des bords et réduire la perte de matières premières.

L'ensemble de la machine a un câblage de type pont, qui est soigné et sûr, avec une conception d'optimisation de la consommation d'énergie, et la puissance de fonctionnement réelle est d'environ 320 kW.

Paramètres techniques

| Catégorie | Détails des paramètres |

| Configuration de l'hôte | Diamètre des vis φ130 mm, rapport d'aspect 33: 1, volume d'extrusion maximum 500 kg / h, puissance de chauffage 52 kW (contrôle de la température du pid à 7 zones) |

| Tête de décès | Longueur 1800 mm, puissance de chauffage 21 kW, plage de température 0-300 ℃, largeur de film 1680 mm |

| Circuit de refroidissement | Capacité du réservoir d'eau en acier inoxydable 1,2 m³, température de l'eau 30-60 ℃ |

| Étirement et mise en forme | Diamètre du rouleau φ420 mm, vitesse de ligne 80-400m / min, puissance de chauffage 72 kW (circulation de l'air chaud à double couche) |

| Système de rembobinage | Enroulement à fréquence variable à 30 broches, moteur à broche unique 120W, diamètre de rouleau maximum 160 mm |

| Dimensions globales de la machine | 48m (longueur) × 6,5 m (largeur) × 3,3 m (hauteur), poids d'environ 50 tonnes |

| Exigences d'électricité | 380 V / 3P / 50Hz, capacité totale installée 600 kW, puissance de fonctionnement 350KW |

| Exigences environnementales | Température ≤40 ℃, altitude ≤ 2000 mètres, atelier propre et sec |

Marque de composante de base

Système de contrôle: Taiwan Delta Plc, écran tactile Kunlun Tongtai

Composants électriques: disjoncteur de Schneider français, contacteur, relais

Système d'entraînement: onduleur de l'inovance en Chine, Siemens Beide Main Motor (160 KW)

Instrument de contrôle de la température: Japon Fuji PID Contrôle de commande de température

Pièces mécaniques: réducteur de Nord allemand, roulement NSK, rouleau à chrome dur

Scénarios applicables

Type de matière première: Nouveaux granules de sac PP, mélange masterbatch

Type de produit: Fil plat en plastique, courroie tissée, matériaux d'emballage, etc.

Application de l'industrie: sac tissé, géotextile, film de couverture agricole, production de ceinture de battement industrielle

Exigences d'installation et de support

Alimentation: Système triphasé à cinq fils, Copper Core Cable Spécifications:

Hôte: 185 mm² × 3 + 150 mm² × 1 + 90 mm² × 1

Compresseur d'air: 16 mm² × 3 + 2,5 mm² × 1

Circulation de l'eau: 50 mm² × 3 + 35 mm² × 1 + 2,5 mm² × 1

Source d'air: alimentation à air ≥ 0,6 m³ / min, fluctuation de pression ± 1ba

Source de l'eau: Volume d'eau ≥ 0,1 m³ / min, pression de l'eau 3-5bar, pH 7,0-7,8