Nouvelle génération de machine de fabrication de sacs de soupape FK008-ⅲ

Gachn Group a lancé une nouvelle génération de machine de fabrication de sacs de soupape FK008-ⅲ avec sa force technique principale et sa riche expérience de l'industrie.

Nom du produit :

New Generation of FK008-Ⅲ Valve Bag Making MachineNuméro d'article :

FK008-IIICommande (MOQ) :

1Paiement :

30% advance payment, 70% balance before shipment or negotiableOrigine du produit :

xiamen,chinaPort d'expédition :

XIAMEN or Or according to your needsDélai de mise en œuvre :

3 monthsNouvelle génération de machine de fabrication de sacs de soupape FK008-ⅲ

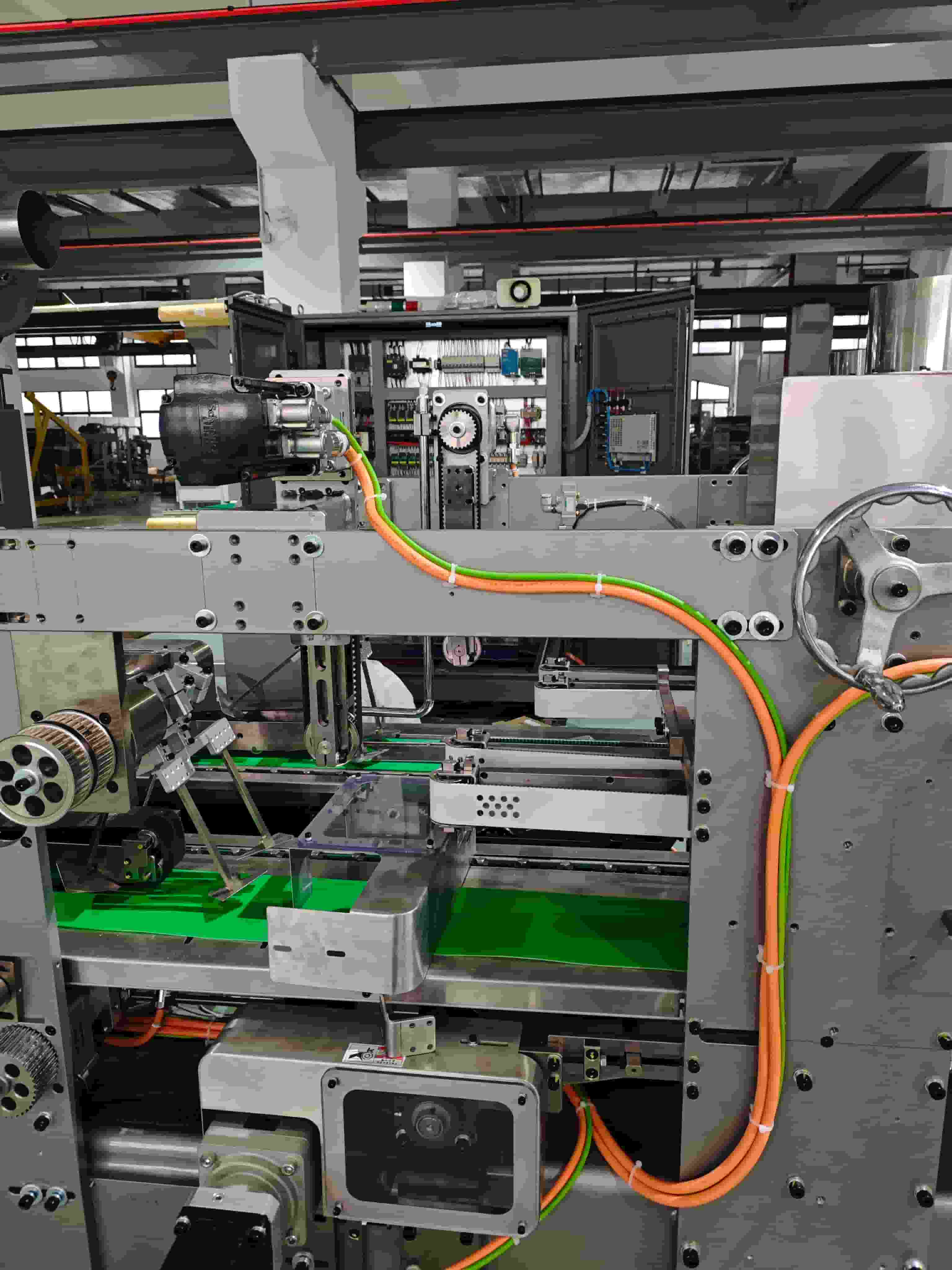

GACHN GROUP, Automatic PP Woven Block Bottom Valve Sack Making Machine Producer, a lancé une nouvelle génération de machine de fabrication de sacs de soupape FK008-ⅲ avec sa principale force technique et sa riche expérience de l'industrie. Il intègre une production efficace, une détection intelligente et un fonctionnement stable, et est largement utilisé dans la production de sacs de soupape dans les champs de produits chimiques, de matériaux de construction, de nourriture, etc. La technologie et la configuration de base sont introduites en détail:

1. Performances et paramètres de base

Points forts du paramètre technique

Production ultra-haute vitesse: vitesse de travail stable de 130 sacs / minute, valeur maximale allant jusqu'à 140 sacs / minute et capacité de production ont augmenté de plus de 14%.

Inspection de la qualité intelligente: Caméra linéaire 4K + système de détection infrarouge, taux de fuite <0,15%, le taux de ferraille réduit au plus bas de l'industrie.

Économie d'énergie et protection de l'environnement: 150 kW de conception de consommation d'énergie à faible énergie, économisant 15% de l'électricité par rapport aux modèles similaires.

Configuration du composant central

| Nom du module | Marque / modèle | Avantages fonctionnels |

| Système d'entraînement servo | Schneider plc précis | Contrôle synchrone, erreur ± 0,1 mm |

| Système d'inspection visuelle | Caméra Eco 4K + source lumineuse Kangshida | Résolution ultra-élevée de 0,17 mm / pixel |

| Composants pneumatiques | Cylindres SMC / Festo | La durabilité a augmenté de 50%, les coûts de maintenance faibles |

Fonctions intelligentes

Prise en charge de l'IoT: module de surveillance à distance en option pour afficher l'état de l'équipement et les données de production en temps réel.

Commutation de type de sac en un clic: écran tactile pour définir des paramètres, adaptés à une variété de spécifications de sacs de 330 à 730 mm.

Clients applicables: grandes entreprises d'emballage, usines avec des exigences de mise à niveau d'automatisation

2. Innovations technologiques clés

Détestage intelligent et contrôle des tensions

Le corps du sac produit par la machine de fabrication de sacs de soupape de sac de soupape de soupape de soupape en bloc tissé PP automatique Gachn Gachn Gachn Adopte le sac à tube du sac à tube (diamètre extérieur maximum 1500 mm), et l'autocollant / autocollant de vanne adopte la feuille de feuille (diamètre extérieur maximum 1100 mm).

Le correcteur d'écart importé (marque BST / FIFE) garantit que l'erreur d'écart des matériaux est ≤ ± 1 mm et que la tige de tension flottante est utilisée pour réaliser une tension constante.

Micro-trou modulaire et soudage précis

Dispositif de poinçonnage à micro-trou: conception modulaire de rouleaux d'aiguille, les dommages locaux peuvent être rapidement remplacés et la précision de réglage atteint la commande numérique du roue à main de la vis.

Soudage à ultra-haute température: arbre de direction contrôlée par servo et buse de soufflage réglable, prends en charge la surveillance de la température en temps réel et la protection de mise hors tension, pour assurer une position de soudage précise et stable.

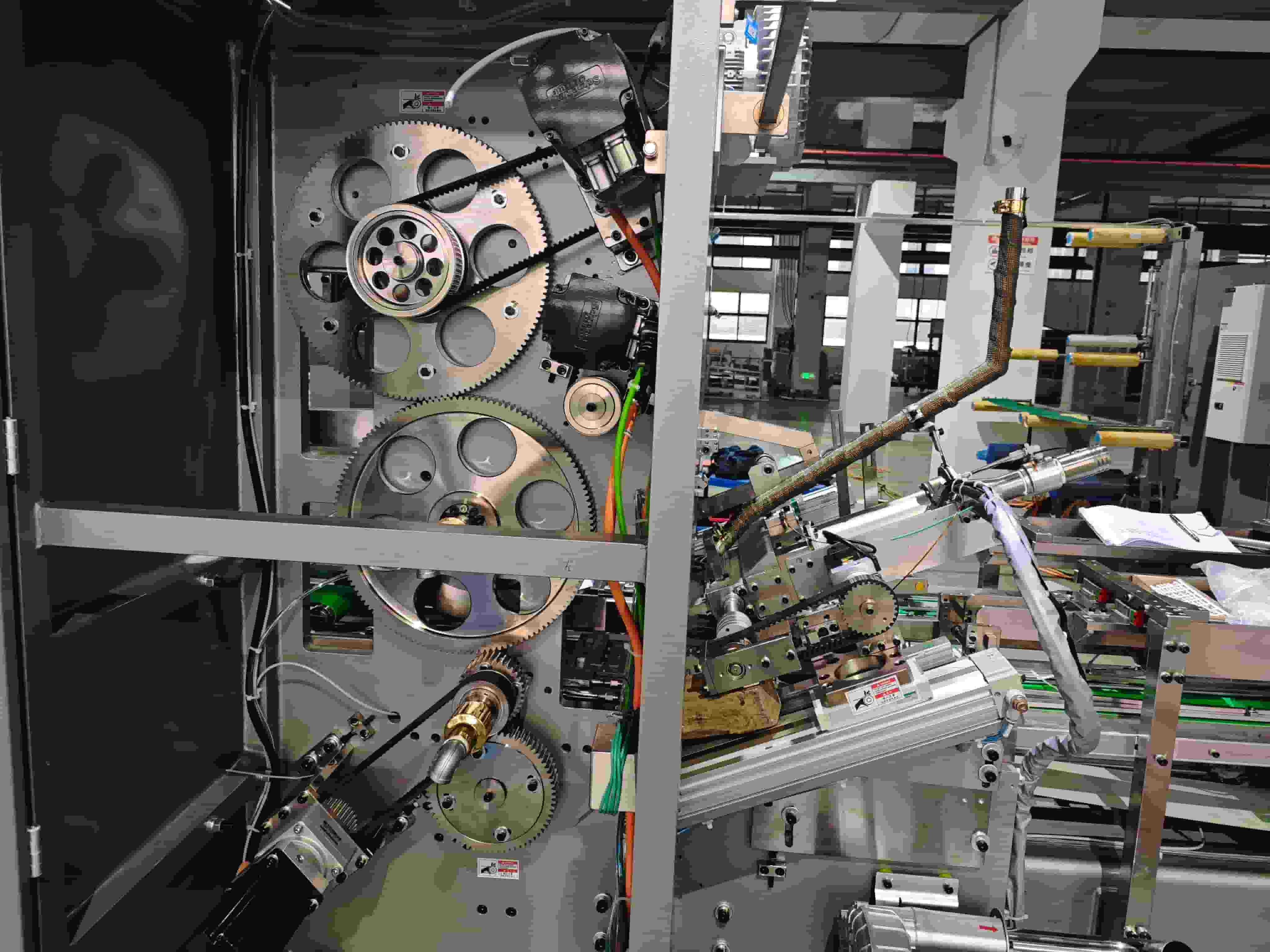

Système complet de service de service

Processus clés (traction, transfert, ouverture des sacs, etc.) Tous utilisent des servomoteurs Schneider et le contrôle segmenté améliore la précision et l'efficacité du mouvement.

Le système de pression négatif sous vide garantit que le corps du sac est transféré sans glisser et coopère avec la détection photoélectrique pour réaliser l'alarme automatique et l'arrêt des défauts.

3. Exigences des matériaux et du processus

Matériaux de fabrication de sacs

Sac de soupape inférieur de bloc tissé pp automatique Agent de la machine Machine GACHN Sac de soupape de vanne Machine peut produire des sacs tissés cylindriques en polyéthylène à 85% + 15% de polypropylène, sans liaison dans la couche intérieure, qui peut être séparée par la frottement légère. 100% sacs PE. Sacs composites en papier.

Technologie de traitement

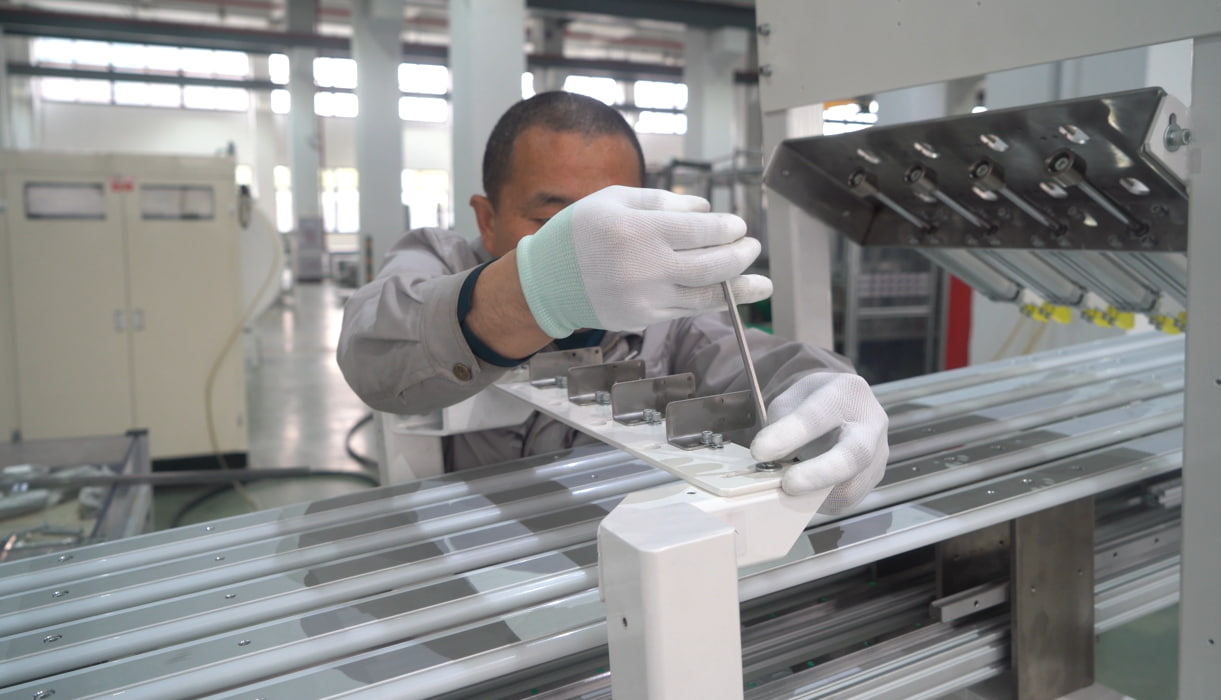

Les pièces mécaniques exposées sont faites de 304 en acier inoxydable ou en chrome / nickel, et les pièces de transmission sont tempérées et renforcées pour assurer la durabilité.

Les composants pneumatiques sont en marque SMC / Festo, et les roulements roulants sont en NSK / NTN pour assurer un fonctionnement stable à long terme.

4. Garantie de renseignement et de sécurité

Conception d'interaction humaine-machine

Interface de fonctionnement chinoise: l'écran tactile et les boutons prennent en charge l'affichage chinois, et le paramètre est pratique.

Protection de la sécurité multiple: conformément à la norme GB5083-1999, couverture de protection en alliage en aluminium + maillage en acier inoxydable, temps de réponse à l'arrêt d'urgence <0,5 seconde.

Empile de produit fini et gestion des données

Le système de transfert de servo prend en charge la quantité d'empilement personnalisée, le comptage précis et la distance de transport réglable.

5. Service et support après-vente

Formation technique

Le fournisseur fournit une formation sur place, la maintenance et le diagnostic des défauts et recommande aux clients de doter le personnel des antécédents d'automatisation au-dessus du niveau collégial.

Engagement de garantie

L'ensemble de la machine est garantie pendant 1 an, le logiciel est amélioré gratuit pendant 3 ans, et les dommages causés par des défauts de conception ou de fabrication sont remplacés gratuitement.

Accessoires aléatoires: boîte à outils standard, un ensemble de pièces de port de pièces, de manuels d'opération chinois et anglais et de données techniques électroniques.

6. Disposition et apparence de l'équipement

Dimensions tridimensionnelles:

12,0 m × 7,5 m × 2,5 m (base réglable pour s'adapter au niveau du site), toute la machine pèse environ 17 tonnes.

Conception d'apparence:

Milky Whik + Spray Grey Silver Gray (prise en charge de la personnalisation), Dissipation de chaleur du climatiseur de l'armoire électrique, spécifications de câblage et maintenance facile.